Shop

Crushing Cones and Crafting Connections: How HPA and HAAS Are Shaping the Future of Hops

A new Garden of Eden.

Like This, Read That:

Hop Central, HPA’s New State-of-the-Art Pelleting Facility, Goes Online for its First Harvest

48 Hours Drinking and Eating in Sydney, Australia

This article has been written in partnership with our friends at HPA and HAAS.

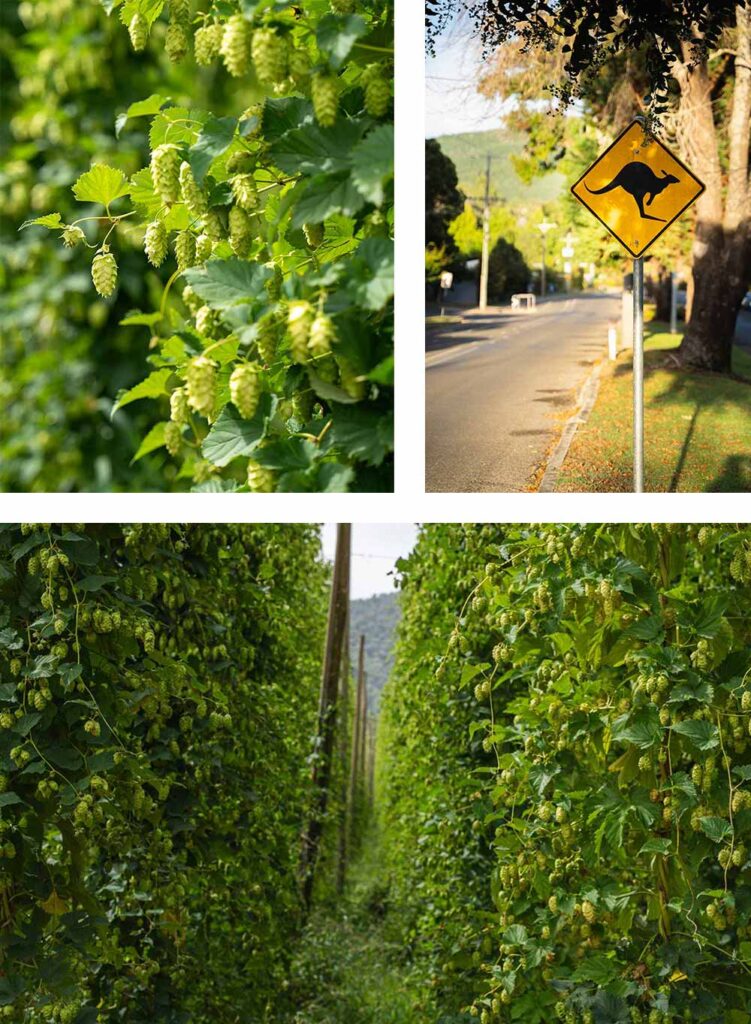

Our bus veers off the dirt path, bumping along the grass several paces before stopping with an audible sigh. We jump off into what can only be described to a group of beer industry folks as a Garden of Eden. In front of us, hops are strung up, standing tall in the sunlight. Little signposts with names we recognized—Galaxy®, Eclipse®, Vic Secret™—and those we didn’t—HPA-050, HPA-033, HPA-4029—directed us into the field. Left to explore, we ambled through the green bines, plucking hop cones off and crushing them in our hands, inhaling aromas of lollipops, passionfruit, and lychee.

Most make a beeline for the very first corridor of Galaxy. With noses stuffed into their cupped hands, everything goes silent for a second, punctuated only by exclamations: Bubblegummy! Juicy! Fruity!

Walking farther down, I notice a group chatting about Topaz. Words like guava and star anise float up.

“It’s like the black sheep of our hop family,” HPA’s Marketing Manager Grace Irwin tells me, admitting she loves this lesser-known Australian hop. “When you use it in higher doses on the dry-hop side, you get these exotic tropical fruit flavors that really shine in session beers.”

Photography courtesy of Magic Muncie, Social Media Manager, Hop Culture (top), James Davidson (bottom left), and Grace Lee-Weitz, Senior Content Editor, Hop Culture (bottom right)

A few rows down in an aisle of an experimental hop called HPA-4029, someone asks about the flavor: “Do you think it’s grape-berry?”

I strike up a conversation with Põhjala Head Brewer Martin Vahtra about another experimental hop we’re checking out, HPA-065.

He’s picked up notes of ginger and lemon. “It’s so different that I would want to try it in an IPA,” he tells me earnestly. “You have so many muddled, overripe, tropical hops anyway. You have Krush, you have Citra, you have Mosaic. All slightly different, but they fill the same void in that sense, so having something completely different is very refreshing.”

Our group of about twenty brewers from around the world—the U.S., Ireland, U.K., Estonia, Croatia, and more—have gathered in what HPA calls its “Showcase,” an area of Rostrevor Hop Gardens where we can get up close and personal with some of Australia’s most popular hops.

Every two years, HPA, Australia’s largest hop grower, and HAAS, North America’s leading hop supplier, lead a group of brewers from around the world to Australia to experience the hop harvest.

Over six days, we visit their hop farms in the Victorian growing region, attend the High Country Hop Festival and High Country Hop Technical Symposium, and get a sneak peek at HPA’s new state-of-the-art pelletizing and processing plant, Hop Central.

What does HAAS’ Commercial Ambassador to HPA Amaey Mundkur hope a trip organized by two of the world’s most significant hop producers will spark?

One word: “Inspiration,” he says.

When you get a chance to spend time in the fields with the agricultural products you use in your brewhouse, you establish connections from the crop to the craft. It leaves an indelible impression.

“This tour is definitely a dream come true,” says St. Louis, MO-based Modern Brewery CEO and President Beamer Eisele as we walk around in awe.

“You see people’s eyes getting bigger,” says Mundkur. “When you rub Eclipse in the fields, you might think differently when writing a recipe in the future; you might be inspired differently.”

Those like Kona Brewing Co. Vice President of Operations Jack Albanese.

When we spoke with Albanese a couple of weeks before the trip, he was excited about the idea of inspiration.

“I’d love to figure out the trends in Australia and how they might dictate what we do here,” he shares, noting Kona currently uses Galaxy in its tried and true flagship, Big Wave. “With beer being such a global beverage, how can I bring some of that to Kona so that we can share it with not just the local community but all the travelers globally who will come here?”

That’s the incredible power at brewers’ fingertips when HPA and HAAS, who both operate under the BarthHaas umbrella, work together.

That inspiration Mundkur spoke about? On a sunny afternoon in March, walking around a few trial plots, we were finding it.

It’s trips like these that can help brewers like Albanese answer a question he’s always asking himself: “What do we think is the next big thing?”

The Big Bang: Transitioning from All Bittering to All Flavor Hops

HPA knows a bit about “that next big thing.”

Today, Australian hops like Galaxy and Eclipse are widely known for their unique flavor characteristics. Those like passionfruit, peach, and even candy-like tones, which are often irreplaceable.

But that wasn’t always the case.

Unlike in North America and Europe, hops are not native to Australia. The country first planted these little green cones in 1803, but those varieties were very different. They focused on bittering.

For instance, Pride of Ringwood—the highest-alpha hop in the world when it first came to market in the 1960s. That hop became the mainstay of Australian hop growing for nearly fifty years.

Former Head of Sales and Marketing and newly appointed HPA CEO Owen Johnston has told Hop Culture in the past that HPA cultivated a very high-alpha program with a secondary goal of replicating Northern Hemisphere varieties like Hallertau Mittelfrüh. If a harvest didn’t go well in Germany, brewers could find a viable derivative in Australia. That’s what the market wanted.

But by the late 2000s, HPA, who by then accounted for ninety percent of Australia’s hop acreage, faced some significant hurdles.

HPA Head of Agronomic Services Simon Whittock, who joined the company in 2007, explains that all the contracts HPA held at the time were alpha-focused. “The business was really struggling,” he says. “The price was such that there was little or no margin in those contracts, and the future volumes were looking wobbly. So we had to find another way.”

Then HPA CEO Tim Lord, who served in that position for nineteen years, made a bold move.

From 2008 to 2021, HPA shifted its acreage from one hundred percent alpha hops to one hundred percent flavor hops.

Johnston calls HPA’s transition a textbook move. With the hop commodity market in a flat spot, “we just couldn’t keep going that way,” he explains. “We needed to find something where we could create a point of difference, and we could create a benefit that people put value on.”

After such a long time prioritizing bittering hops, the market had changed. Flavor-forward hops like Nelson Sauvin, Citra, and Amarillo were making waves. “People started to see that hops could do something other than bittering and European aroma and make a profit for a brewery,” says Whittock. “The market was primed.”

Johnston puts the decision more simply: “Let’s have a shot at this. Let’s have a crack. And worst case scenario, my ego will take a big battering and I’ll have to eat some humble pie.” But the rewards seemed worth more than potential ruin.

Spoiler alert: It worked.

In a Galaxy Far, Far Away

Photography courtesy of Magic Muncie, Social Media Manager, Hop Culture

Name an Australian hop off the top of your head.

Did you think of Galaxy?

Currently one of the most recognized Australian hops worldwide, Galaxy was created by HPA in 1994, hitting the commercial market in 2009.

A cross-pollination of high-alpha Australian and Perle parents, Galaxy changed everything for HPA.

Amid a transition, Galaxy became the star.

Tropical fruit-forward flavors that seem commonplace now among Australian hops didn’t exist then.

Galaxy filled a void. And the timing couldn’t have been more perfect.

Think about it. In the early 2010s, the craft beer industry favored Pacific Northwest varieties like Cascade, Citra, Chinook, and Centennial for American and West Coast-style IPAs. But by 2015, with the advent of hazies, brewers searched for those bright, juicy, more citrus-centered hops.

Galaxy took that sought-after matrix to the next level…to an entirely new stratosphere, if you will.

Albanese remembers his first time experiencing Galaxy around 2012 or 2013.

Working at the time at Terrapin Beer Co., Albanese wanted to bring sessionability to the brewery’s IPAs. Thick into higher-gravity dank IPAs with a lot of crystal malt and “heavy” hops, Albanese says they looked for something brighter, an IPA you could drink after riding your bikes or hiking.

“Getting Galaxy and smelling it was just like, whoa,” says Albanese. “It felt like a thirst-quenching opportunity.”

In Tallinn, Estonia, Vahtra had a similar revelatory experience. “Even before opening the bag, I was blown away by the alpha acid content,” he says. “When I finally poured the hops into the whirlpool, I was overcome with the vivid and bright aroma of ripe passionfruit and lemongrass, which I hadn’t come across in hops before.”

Beers just pop with Galaxy. Think of brewing with this hop like adding the perfect amount of salt to a recipe. Once you sprinkle just the right amount of crystals, you’ll create a dish that sings.

A game changer when it hit the market, Galaxy put HPA on the map, for better or for worse.

As the hop grew in popularity and demand over the years, it’s no secret that the quality fluctuated.

If Lord saw HPA through, among other things, a significant transition away from bittering towards flavoring hops, Johnston wants his primary focus as HPA’s newly appointed CEO to be restoring the brewing world’s confidence in quality, especially with Galaxy.

In a Galaxy Close to Home

Photography courtesy of James Davidson

HPA has started an intensive, years-long process to update its equipment, technology, procedures, and quality management systems.

“This is the new frontier for us,” says Johnston, who acknowledges that the Galaxy crop had a few rough years that damaged people’s trust and confidence.

HPA has already taken several significant steps.

For the first time during the 2025 harvest, Hop Central, HPA’s new state-of-the-art pelletizing and processing plant, came online.

The $20 million (AUD) project covers 22,000 square meters (236,806 square feet) with top-of-the-line equipment dedicated to pelleting and packaging HPA’s entire crop, doubling the grower’s current processing capacity.

In 2025, for its first full harvest, Hop Central pelletized and packaged hops from HPA’s Victorian and Tasmanian growing regions, totaling 566 hectares and 1,468 metric tons. The plant can process up to 50 tonnes of pellets per day, with HPA aiming to pelletize the entire crop of hops within 55 days, more than 35% faster than the 70 to 80 days it took at HPA’s two older plants.

The large-scale project will, among other things, increase efficiency by switching from manual labor to almost all-automatic machinery, preserve hop integrity through a one-hundred-percent cold-chain environment, ensure consistency through robust blending, and maintain quality through upgraded packaging.

Johnston calls the plant the “once-in-a-generational piece of the puzzle that’s falling into place now.”

He adds, “We’re owning our problems and out there telling people what we’re doing to address them. If we can help people understand where we’re making improvements, we can build their confidence.”

But Johnston doesn’t just want to tell brewers that Galaxy’s quality has improved.

“Let me prove it to you,” he says.

Põhjala’s Vahtra shares how, while he loves Galaxy’s expressions and aromatics, in the past he only used it sparingly in one-off releases or as small accents in core beers because he came to expect that no two years were truly alike.

“I didn’t have the confidence that I would be able to source a similar lot the following year,” he says.

After traveling to Australia for the hop harvest, he has a new perspective.

“The visit to Hop Central really brought all of the puzzle pieces together for me, and revealed HPA’s long-time initiative of achieving true to brand flavour consistency between different lots,” says Vahtra, noting he has seen a more consistent flavor profile in Galaxy for the last couple of years.

Vahtra explains how HPA is essentially blending various Galaxy bales based on comprehensive sensory and technical data to create pellet lots with as uniform and true-to-type profiles as possible. With this approach, “Not only have average hop oil quantities gone up, harvest to package time has gone down, meaning everybody is receiving fresher hops,” says Vahtra, “but this innovative approach potentially also eliminates the necessity for hop selection, making high-quality hops a lot more approachable to small independent breweries.”

In other words, the tides are starting to change.

A Rising Tide Lifts All Hops

Photography courtesy of Magic Muncie, Social Media Manager, Hop Culture

At the center of all these changes, Johnston recognizes how HPA’s partnership with the BarthHaas group, which purchased growing assets in Australia in 1988, has provided immeasurable benefits for HPA.

Under the BarthHaas group, HPA has access to resources from its partner in Germany and HAAS in North America.

“For a little Australian hop farmer, we have this global reach,” says Johnston. “We can also use their marketing platforms and their voice in the market to tell our stories.”

With HAAS specifically, Johnston points out that the relationship helps HPA present its products and messages to a big beer-drinking country all the way across the Pacific Ocean.

“We get an immense benefit because they service the entire Americas for us,” he says.

Shared resources mean that HPA can call up forty-five-year-industry-veteran Brice Hiatt, HAAS director of pellet operations, known as the Hop Whisperer, to ask for advice on designing its new Hop Central facility.

Hiatt, who had recently overseen the construction of a new pelletizing line at HAAS’ facility in Yakima Valley, shared what he’d learned over his twenty-seven-year experience as HAAS’ plant manager with the HPA team.

“One thing that is very important is consistency,” explains HAAS Sensory Manager Jeff Dailey, who also recognizes that Galaxy had some quality issues over the last five to seven years.

Dailey explains how HPA and Hop Central can be a point of centralized management capable of executing harvest, irrigation, quality control, and growing, all under one “roof,” so to speak. “They can create the consistency … that American brewers need,” he says. “Whether they’re buying hops on the spot market or contracting, brewers can expect consistency bag to bag, carton to carton, and pallet to pallet; they’re not in a position where they’re rolling the dice.”

HAAS’ Dailey will be offering another resource to the HPA team, recently traveling down to Australia with Associate Sensory Scientist Rikki Welz to train the HPA team on his Sensory Plus Program, a system of sensory evaluations and quality control performed by well-trained individuals who can then share knowledge with brewers, helping them make informed choices on desired lots.

“Their noses are just amazing,” says Irwin.

The goal is that in a couple of years, the HPA team will be running its own year-round sensory program.

“We want to make an impact now, demonstrating to the world that Galaxy is back, that Eclipse is awesome, that we’ve got some amazing experimental hops in the pipeline,” shares Dailey. “If we can prove the value of the sensory-based program and the value of implementing full Sensory Plus down there, then I’m confident that within two or three years we can establish an independent Sensory Plus Program out of HPA.”

Dailey says the relationship between HAAS and HPA is very much a two-way street, giving American brewers a direct pipeline to some of the world’s most popular hops.

“HPA is an amazing opportunity for us,” he says. “We can work together to breed new varieties that take advantage of their unique growing environment in the Southern hemisphere.”

Six Days, Countless Stories, Many New Beers

Photography courtesy of Magic Muncie, Social Media Manager, Hop Culture

Inspiration.

That’s what HAAS Commercial Ambassador to HPA Mundkur hoped brewers would get out of this six-day trip to the bottom of the world.

Did we? Well, you tell us.

Two weeks later, in our group WhatsApp chat, Modern Brewery’s Eisele sent a photo of a new lager he’s working on with four pounds per barrel of Galaxy.

I bumped into Albanese a month later at America’s largest beer industry conference, CBC. Inspired by his time in Australia, he excitedly told me about all his ideas for making a lower-alcohol beer at Kona.

Kona is also getting ready to launch its first seasonal hazy IPA, where Albanese says he hopes to use Galaxy. “We want to bring differentiation to that beer,” he told me.

Likewise, since the trip, Vahtra told me that his “newfound enthusiasm for Aussie hops” means he’s planning to feature them in more of Põhjala’s upcoming releases, including a West Coast-style IPA that will heavily focus on Eclipse hops. “It’s very easy to appreciate just how distinct and impactful the character of Australian hop varieties truly are,” says Vahtra of his time at hop harvest, “but what was really eye-opening to me was how much dedication and work HPA is pouring into the pursuit of true-to-type flavour profiles and year-to-year consistency for each hop variety.”

Although thousands of miles separated us, across oceans and continents, this HPA and HAAS trip brought us together.

And together, we left inspired by hops, and inspired by what’s to come.

“Hops are part of what will make beer successful,” shares Johnston. “So I think we have a great future.”