This content was originally published by The Hop Review, a digital magazine that joined the Hop Culture family in March 2020.

This piece was written by Jack Muldowney.

BOWMANVILLE, CHICAGO

75th interview

INTERVIEWED FEBRUARY 12, 2016

AT HALF ACRE BALMORAL – CHICAGO

Half Acre Beer Company is something of an institution in Chicago. While the first beers in the early days of the company were actually brewed in Wisconsin, the city’s identity has been firmly imprinted on the Northcenter brewery since its 2008 opening. Great beer paired with perfect timing for the incredible boom of the craft scene in Chicago meant that by 2012, HABC had outgrown their original facility and was looking for a new home. They’ve found that home a mile and half north in the Bowmanville neighborhood. The huge new production facility now supplies the majority of beer to Half Acre’s ever increasing distribution footprint, freeing up the Lincoln brewery to experiment.

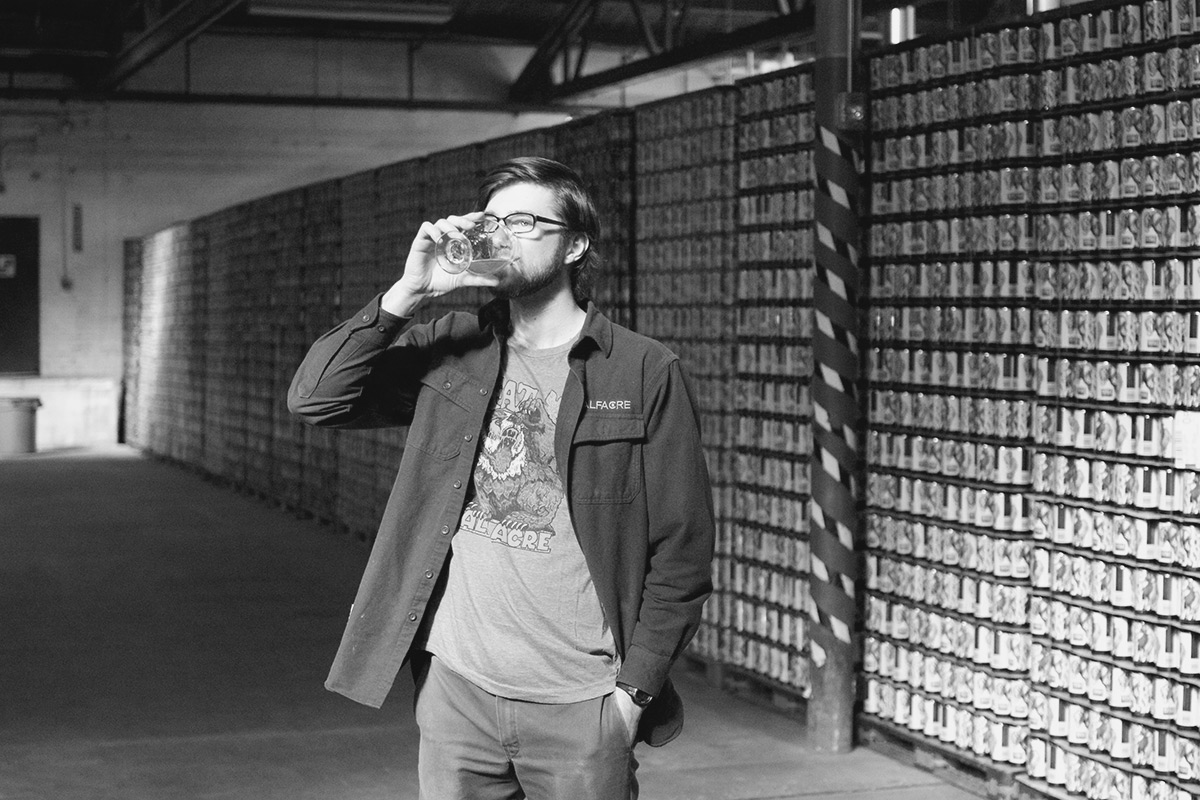

At the forefront of that incredible growth is Head Brewer Matt Young, one of Half Acre’s earliest “deckhands” who’s worked his way to the top of the brewing ladder. We stopped by Bowmanville and, over bottles of Double Daisy Cutter, asked Matt why he left grad school to clean floors, how Half Acre has changed since he started, and why he loves the brewery he calls family.

How long have you been with Half Acre?

I’ve been here for over five years now. I was in graduate school before for Molecular Biology. I decided that wasn’t really for me and I didn’t want to spend the next seven years it was going to take to get my PhD. I decided I really wanted to have a job in a craft brewery. So, I had to use this science background and started feeling out what’s available, which, back in 2010, was not a lot in Chicago. There was Metropolitan, Half Acre, Goose Island, and Revolution had just started their brewpub.

But why a craft brewery? That’s quite the leap.

Well I’d read all the books that I could and I did a lot of homebrewing. I took a brewing class during undergrad, which was pretty sweet. They actually have a Fermentation Science degree now at Western Kentucky University, where I went to school. But before that, they were just kind of testing the waters by offering an upper level biology course. It was called The History and Science of Beer and Brewing. It was taught by two professors in history and microbiology. They’d break it up and talk about beer in the 1400’s, and then have some sort of science lesson on the process of creating beer. Then we’d homebrew a certain style in class and taste commercial examples versus our homebrew examples.

Wow, we really missed out during our undergrad days. So you really must have seen it all at Half Acre over the last five years.

All but the first couple years, yeah. I’ve seen a lot of the growth. The first year I worked at the brewery, we produced about 3- to 4,000 barrels of beer. Last year, combined between the Lincoln and Balmoral facilities, we did around 24,000 barrels. So we’ve grown quite a bit, and grown in staff as well.

What will be your full capacity once this place is full?

Space wise, it could be a very large number… but I don’t know if that’s what we’ll actually get to. We don’t plan on taking over the world or anything. We’re just filling out Chicagoland, and now distributing throughout the state of Illinois. We’ve had beer in Philadelphia for a while and we’ll be going into the New York City market soon.

What does your day look like now? You must be one busy man.

My day is all over the place. I still brew and cellar here. I’m also overseeing the production stuff here. That consists of deciding what we need to brew and working with the Director of Operations and with our Sales Director to decide what needs to be brewed. And then I’m just steering us to improve quality in anyway we can and improve our processes.

Half Acre has really become one of the go-to beers in the city–and it’s great you’ve been able to achieve that first, before expanding.

For sure, and it feels great to be able to do that. Obviously it’s great culturally for us to be a well known brewery in the city where we exist. And also for the quality of our beer, to know it’s being consumed fresh and not having to travel very far, is also great. It’s a peace of mind thing, especially as we’re making more beer now. We’re working really hard on quality and trying to understand our beers a little bit more.

What’s the biggest challenge managing consistency on this expanding scale?

Well, I think the scale for us isn’t that dramatic. We have a 30-barrel brewhouse here. We still have a 15-barrel brewhouse at the original Lincoln Ave. brewery. So I guess we did double in size in terms of each batch produced, but I don’t think that’s as dramatic as some breweries that make the leap. We spent the last year working really hard, making sure things taste the same–whether they’re brewed at Lincoln or here.

How are you splitting the brewing between the two locations now?

The way it breaks out is, over here we make all the canned beer, because it’s where our canning line is. We also do the larger speciality batch beers over here. That would consist of beers like Double Daisy Cutter and Antoine’s Baumé. We do one of those types of beers a month and that goes in the 22 oz. bombers. They’re beers we’ve made before that we really like and are trying to distribute a little more widely throughout the city rather than just sell at the shop.

“There was about a 48 hour period, starting out as deckhand, where I had some doubts about my decisions. But ever since then it’s pretty much the greatest job I could ever imagine having.”

So Lincoln is reserved for small-batch brews now?

We still do occasional small batches here of stuff that doesn’t go into bottles, but most of that is now happening exclusively at the Lincoln Avenue brewery. So all the stuff we’re brewing over there is either stuff we’ve brewed before and wanted to return to in a small batch format, or it’s things we’ve never made before. As we go on, it will only continue to be more things we’ve never made before. We’re building a little bottling machine over there so we can bottle a small amount of those beers in bombers.

Anything special in the works you can tell us about?

We do have a room that we’ve dedicated to barrel-aging things, all in wine barrels with mixed cultures. That doesn’t really have a timeline yet–on when those beers will be coming out of that program–but it’s definitely something that we’re investigating. Some of these beers are sitting in barrels upwards of a year and a half.

The potential volume of production in a space this large is staggering, especially compared to the original brewery. How long were you at capacity over at Lincoln?

We were maxed out for about two years. That was a great time though. It was really hectic and just insane to be working shoulder to shoulder, but was awesome. We took advantage of the fact that we couldn’t make more beer, and chose to focus more on the beer we were making. We really dialed it in, and got ready for this next step.

Was there a nervous feeling when you first came into this huge new facility, and thought “Oh shit, this is a lot of space to fill”?

For sure, yeah. We were sort of diving into the unknown. But one of the things I love about working here is Matt [Gallagher] and Gabriel [Magliaro], the owners, value everyone’s opinions. They realize how a change like this is going to affect everyone’s work lives. But it was really, “If we want to make more beer, we need to do something.” The transition was difficult at first. It was way more lonely than it is now.

Now it’s a really energetic brewery.

Aside from the crowded brewery, what’s something that you’re glad you don’t have to worry about now you’ve expanded?

Probably just when we brew high gravity beers over there. It’s just so much labor, so much effort. And all for such little payoff because the mash tun over there is not efficient at all. You almost need to mash twice as much grain just to make 50% stronger wort. Over here, with the same amount of effort, we can make strong beer, low gravity beer, middle of the road beer…all of it is going to be consistent. It’s really amazing.

We’re also really efficient here in other ways.

We’ve got an in-house wood shop. We’ve got a woodworker on staff, even. We got some wood from a building that was torn down on Milwaukee Avenue, so we’ve been making things out of it. Tables, displays, mash paddles–all sorts of things that are needed over at Lincoln Avenue.

Wow, certainly the first in-house brewery wood shop we’ve seen to date… Speaking of–what is the story to the wooden feature wall in the taproom over at Lincoln? From a grain silo, correct?

Yea, those are three single panels that arrived that way to us on a flatbed trailer. They were part of a grain elevator in Wisconsin. So, for 100 years, grain passed over the surface of that wood and wore that texture into it.

Wait ’til I take you guys through the leather shop…hah. I’m not kidding…

You’ve already mentioned quality and consistency a couple times now. How long did it take to brew Daisy Cutter here at Balmoral in the exact same way you did at Lincoln?

We’re still working on it, to be honest. We have a really good sensory program now so we’re able to brew a batch at Lincoln, brew a batch here, and do an official blind tasting with all the people that work here. We want to see if they can pick out the Lincoln batch from the Balmoral batch. Hopefully not, but we’re still kind of in that territory where people think there’s a difference. There’s not a dramatic difference at all, which I think is amazing for the different sort of equipment we have to brew versus over there.

A lot of newer Chicago craft fans would likely list a Half Acre brew as one of their first eye openers. Was there a beer that turned you onto the scene?

The first beer that really got me into ‘craft’ was Goose Island IPA, back in Kentucky.

That’s pretty cool that you were drinking a Chicago beer in Kentucky, and now you’re here, brewing one.

Oh yeah. I’d just never had anything with so much flavor, something so bitter. I hated it, but I loved it. I hated it but I wanted to go back and see what that was and have another bottle.

“The things that keep me excited are making this place run as well as it possibly can and improving the workplace environment for everyone that works here.”

So you’ve gone from PhD candidate to Head Brewer. What happened along the way?

When I left grad school, I came to Half Acre as the “deckhand.” That just meant scrubbing the floors that no one else wanted to scrub, cleaning kegs, and all that stuff. There were only three people working in the brewery at that time. Things kind of progressed pretty rapidly for me and I was able to get my hands on more packaging stuff, then get myself in the cellar, then start brewing.

So what’s next for you? That’s some progress already, for a five year career.

Yeah, I hope to stay in this position. I brew because I like to brew. Even Matt, one of the founders, still makes sure I schedule him in for one brew shift a week, just because he likes doing it. It’s probably not very practical for him to be doing that at this point but he just wants to be there.

What’s the most exciting thing happening for you at Half Acre?

It’s everything. This place is still so new to everyone. It’s only been a year. There’s just so much to do. The things that keep me excited are making this place run as well as it possibly can and improving the workplace environment for everyone that works here. Everyone that works in the brewery are a really tight knit group. As much as we all try to focus on making beer, we also spend just as much time trying to focus on making sure everyone’s happy and feels good about their workplace. The challenge of growing, is that, with bigger scale comes with the need to hire more people, and there’s the risk of losing the culture you’ve developed. We focus so much on not losing that culture right now. It’s top priority, that’s why we’re all here. We love our jobs. That’s what makes Half Acre great. Everyone here is super passionate about beer and being a part of craft beer. They’re proud to have the workplace we have and the beer we make. It sort of reciprocates on itself.

Any regrets about dropping out of your PhD program and coming here?

Well they did let me have a Masters degree when I dropped out so that was ok. There was about a 48 hour period, starting out as deckhand, where I had some doubts about my decisions. But ever since then it’s pretty much the greatest job I could ever imagine having.

“We took advantage of the fact that we couldn’t make more beer, and chose to focus more on the beer we were making. We really dialed it in, and got ready for this next step.”

Half Acre Lager–this was one of the first Chicago beers we remember seeing on the shelves when we first moved to Chicago, no frame of reference for who Half Acre even was at the time. Since then, we’ve only seen it once or twice. What’s the deal?…

So, what’s up with the lager? The lager, as well as Over Ale, were the first two beers that Half Acre made before I worked here–this was before Half Acre even had a physical location, so it was just to get things off the ground. Gabriel worked with Sand Creek Brewing in Wisconsin to brew those two for us. That was of course until we opened the space on Lincoln Avenue. Over Ale had a pretty good run for us, and we’d canned that for a while. Lager unfortunately never made it into cans, but we still bring it back sometimes just for fun.

We were big fans of Over Ale and were sad to see that one go away.

Yeah—that one and Gossamer. We still make them occasionally, but just in kegs.

Wow, forgot about Gossamer until just now actually. Yea, it was definitely Daisy Cutter & Gossamer for us for a long time. Akari Shogun has sort of taken the place of it now, though, as a summer beer.

Yeah, Akari, or Pony Pils. Pony is a year-round for us, but it’s a little less hoppy. Still hoppy ya know, but just…less. We still like beers like Gossamer and Over Ale, but it just seemed as we brewed more and got more creative, that there were just other beers that we would rather have in our canned lineup.

So, you’re wearing a Sticky Fat shirt now. If you had to choose any one Half Acre beer as your ‘all-year-beer,’ what’d it be?

Oh…aside from Pony, I’d have to go with Tuna. Tuna is our ‘extra’ pale ale. It’s sort of picking up momentum. It’s still a specialty beer but we seem to be making it more often. It’s not extra pale in color, but in the body—we were trying to make it low in alcohol but not lose anything in mouthfeel or flavor. It’s sessionable, in the low 4’s for ABV.

If you’re not drinking Half Acre outside of work, what are you drinking?

Well, I’ll often bring Half Acre home, hah. But if you looked in my fridge you’d find some Sierra Nevada — usually one of their pilsners like Nooner, some Firestone Walker…and some Miller High Life. Sierra Nevada is a brewery that I feel like we all kinda look up to the most in brewing.

What’s your favorite beer spot in the city?

Favorite beer bar? The Long Room. I love their witty beer menu descriptions, and I’ll often find myself making the trip over from Avondale to have beers there.

I’m curious about the neighborhood. When you say ‘Bowmanville’ to a lot of people and you’ll often get, “What? Where?”

Yea, it’s a really beautiful community. You’ve got the cemetery that takes up a lot of it to the north here. But otherwise it’s a really nice mix of gritty and landscaped-gardener’s-residence feel to it. You’ve got the Temple Steel plant at the end of the street, too. So, it’s a neat mix of industry and neighborhood. Kinda has an unpolished feel.

But the neighbors have been really welcoming. We did a local Bowmanville Oktoberfest event where we poured beer and everyone seemed really excited to have us here. They kept saying how excited they were that we’ll have a restaurant in here, too.

And nearby you’ve got Aquanaut, Empirical, Metropolitan, and even Band of Bohemia. And soon you’ll have new neighbors here, literally, in Spiteful Brewing. Building out a real brewery haven up here.

Yea, Northcenter & South Loop are kinda the same, too. It’ll be great around here.

That’ll make for a nice little walking tour… Having Spiteful next door to you guys will be pretty great. Great things happening for you guys in Bowmanville.

Yea, we can’t wait, it’s gonna be sweet. Right across the parking lot…

-THR-

Photography by Jack Muldowney.

Cheers to Matt for taking us on a Friday afternoon tour through the cavernous Balmoral brewery. Look for Matt and the rest of the Half Acre crew afterhours at the Lincoln taproom and keep on eye on the Half Acre blog for new beer releases and updates on the impending restaurant at the production facility.