Shop

What Is a Lager Coolship?

Coolships aren't only for wild ales!

Looking for More Top Content?

Hot wort comes bellowing out of the kettle at boiling temperatures and into a large, stainless steel vessel. The steam rises as the wort cascades across the shallow container, filling every corner and rising up the thin walls. This is the process of filling up a lager coolship.

Let’s get the pun out of the way early on: coolships are pretty darn cool. While historically, coolships had a very specific purpose, modern brewers are finding new creative ways to use them.

If you know the term “coolship” (anglicized version of the Dutch/Flemish koelschip), it’s probably because you’re familiar with spontaneous fermentation. The process of wildly fermenting beer requires a coolship, or flat, wide vessel, where the wort sits while it ferments. What you may not know is that brewers use coolships for way more than just naturally fermenting ales; you can put lagers in coolships, too.

Using Coolships for Wild Ale vs Lager

There are some key differences in using a coolship for wild ales versus lagers. For wild ales, brewers primarily use a coolship to cool the wort, allowing wild yeast to begin inoculation. This process happens over a long period of time as the wort slowly cools down to fermentation temperatures in the 60-70°F/15-21°C range. Many breweries producing wild or spontaneous beers only brew them during the cooler times of the year.

On the other hand, lager coolshipped beer has no need for cooler temperatures, even though they are fermented at much cooler temperatures than ales. The key difference is that coolshipped lagers in modern times will only stay in the coolship for an hour, maybe two tops before being further chilled and sent to the fermenter.

The History of Coolship Brewing

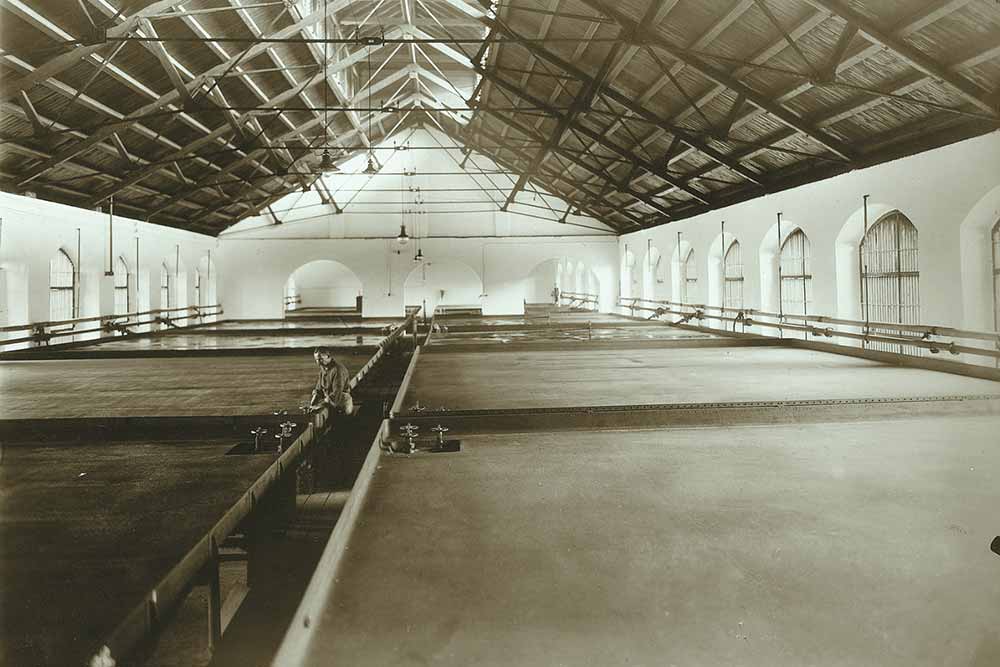

Coolship at Pilsner Urquell | Photography courtesy of Archive of the Plzeňský Prazdroj joint-stock company

Brewing with coolships dates back centuries, before brewers even made lagers. Originally, coolships well, served as the primary piece of equipment to cool down the wort.

Coolships were so prominent, in fact, that Czech brewing historian Milan Starec says in nineteenth century Bohemia, they even had a special line for measuring taxes, called ‘hama.’ “A financial officer had to come to the start of each brew to measure the final volume,” says Starec. “In the old breweries, financial control even had its own room [in the brewhouse].”

Starec says that lager coolships were primarily built from wood until sometime around the mid-nineteenth century, when iron and copper became more common.

At the brewery he owns, Černokostelecký Pivovar, Starec facilitates a brewing museum on-site with an iron coolship last used in 1987. Starec recently had the coolship repaired, filling in holes in a very labor-intensive way with a hammer and rivets to prevent rusting. “The old brewmasters took bricks and scraped off the rust down to raw iron,” says Starec, noting they then brewed several batches with just boiling water and whole hops to add a protective layer of beer stone to the iron.

How Coolships Almost Vanished

A Baudelot Chiller at OEC | Photography courtesy of @oecbrewing

Although brewers primarily used coolships to cool down wort to fermentation temperatures, they had one drawback: wild yeast would often contaminate the beer. While those looking to spontaneously ferment would find this necessary, most brewers didn’t want wild contamination in their ales.

Luckily for brewers, in the mid-nineteenth century, Jean Louis Baudelot invented the Baudelot cooler. The new piece of equipment cooled wort quickly, minimizing the risk of unwanted microbes in the beer.

Towards the later half of the twentieth century, a combination of factors spelled trouble for the popularity of coolships. Newer technologies, such as heat exchangers, became more prevalent. At the same time, breweries were looking to improve processes and further minimize unwanted bacteria in the beers. Space was also a consideration for some breweries, as coolships can take up quite a bit of real estate. Starec points out another reason for the decline. “During communism, you could not make the things that you wanted. It was regulated by the communist leaders,” he says. “The leadership of the communist government decided to close our brewery at this time, so it was never modernized.”

Where You Can Find Lager Coolships in America?

The coolship at Jack’s Abby | Photography courtesy of Jack’s Abby

Luckily, much as Cantillon revived lambic, brewers didn’t completely let coolships die out.

Between Bohemia and Franconia, there are still at least a few dozen breweries using these coolships for lagers, not to mention several others across Europe. Uerige in Dusseldorf and Augustiner in Salzburg are two well-known breweries that use a coolship for all of the beer that they produce.

More recently, you’ll find a few American brewers keeping the practice alive, using coolships to lager in different ways.

Jack’s Abby in Framingham, MA

Jack Hendler clearly has an affinity for his coolship. The founding brewer of Jack’s Abby, a brewery that only makes lagers, would use the coolship more if he could. “As much as I would’ve liked to, I didn’t get approval for a coolship for our main brewhouse, so we only have one for our [seven-barrel] pilot brewery.” Hendler lets the wort sit in the coolship for sixty to ninety minutes, not allowing it to drop below 140°F/60°C, before further cooling it and sending it to the fermenter.

The co-author of the upcoming book Modern Lager Beer, Hendler made sure to cover lager coolships, talking about how different breweries in the world use them and why. “Some breweries just said it’s too expensive to replace this [equipment],” says Hendler. “Others feel it’s an integral part of the flavor of their beer.”

Hendler sees adding hops to the coolship at Jack’s Abby as a way to manipulate the hop profile in the beer. “You get a different hop character,” he says. “Less bitterness and more aroma, the hops settle to the bottom [of the coolship] pretty quickly.”

Otherwise, Hendler observes that there’s a much better dropping out of the unwanted solids when you run the wort through a coolship. “It’s crystal clear coming out of the coolship, much clearer than if we ran a whirlpool.”

Jack’s Abby only releases coolship-brewed beers at its taproom.

OEC Brewing in Oxford, CT

The coolship and Baudelot chiller at OEC Brewing | Photography courtesy of @oecbrewing

OEC Brewing runs every single beer it makes through its coolship, not just lagers. “We have a system that is both modern and kind of old at the same time,” says owner and head brewer Ben Neidhart.

That system is a custom Kaspar Schulz from Bamberg, Germany. “It actually combats DMS twice,” says Neidhart, referring to dimethyl sulfide, an unwanted compound in beer that often tastes like creamed or canned corn in the finished beer. The system at OEC has a pump that recirculates wort over a dispersion plate, pushing it against the sides of the kettle in a thin stream and dropping it back into the kettle. “It’s supposed to simulate a coolship,” says Neidhart. And then, of course, OEC has the coolship too, where he says spreading the wort out wide with a pretty shallow surface blows a nice amount of DMS off of it.

Neidhart notices that the wort darkens a bit in the copper coolship. He says if he didn’t have both an interior direct-fire copper bottom in the kettle and a copper coolship, he’d likely have to adjust the beer recipes to add more caramel malt, as both of those things provide some caramelization to the end beer. “There’s more of a malt body to the beer,” he says.

Neidhart also calculates the hop bitterness extraction a bit higher, especially in the five-minute kettle additions, since the wort will be sitting in the coolship for about an hour. “I get more bitterness out of those hops towards flameout than if it was just a whirlpool,” he says.

OEC allows the wort to chill to about 149°F/65°C before chilling it with a copper Baudelot chiller, perhaps the only chiller of its kind in the U.S. Kaspar Schulz also made that for OEC; its first production of the chiller in over half a century.

Wild Provisions Beer Project in Boulder, CO

Wild Provisions Beer Project’s coolship | Photography courtesy of Wild Provisions Beer Project

Of all the U.S. breweries, Wild Provisions uses its lager coolship in the most unique way. The coolship sits in a positive pressure room, which also houses its small (12bbl) and large (30bbl) open fermenters.

Wild Provisions brews the wort at parent brewery 4 Noses Brewing in nearby Broomfield before toting it over to its own brewery in two rectangular tanks on a big red truck.

“We start with RO water, then sparge with municipal water,” says operations manager Max McAvoy. “All of our Czech lagers are triple decocted. We use Raven pilsner malt and Czech Saaz hops,” he adds.

After arriving at Wild Provisions, the wort is chilled through a heat exchanger as it goes into the coolship to about 70-80°F/21-27°C, depending on the groundwater temperature. There, it sits for sixty to ninety minutes. “The main process point for the coolship is clarification,” explains McAvoy. “The [unwanted] cold break separates to the sides and into the trough.”

Before moving full-time to his brewery, Primitive Beer, Brandon Boldt was the head brewer at Wild Provisions and helped design both the lager coolship, as well as a separate coolship for wild beer. Boldt says he also designed the system to naturally aerate the wort.

“There’s a glycol fin [on the coolship] that can quickly reduce the temperature into the forties Fahrenheit to start lager fermentation like they would in the Pilsner Urquell caves,” says Boldt. While the fin isn’t exactly historical, the setup is modeled after the coolship-to-Baudelot-chiller system, taking historical inspiration and using it in a modern way.

Weston Ring runs the cellar at Wild Provisions and is responsible for both the lager and spontaneous coolships.

“The day I’m receiving the wort, I run sanitizer throughout the entire room,” says Ring. He adds that they’ve run PCR tests for wild contaminants and other bacteria on the lager batches and have never had a positive result.

Dovetail Brewery in Chicago, IL

Dovetail Brewery coolship | Photography courtesy of Dovetail Brewery

Dovetail Brewery runs every beer through its coolship, no matter the style. “I like to call our coolship a Dual-ship,” says Dovetail Brewer and Marketing and Creative Manager Jenny Pfafflin,

Wort is pumped up to the coolship on the second floor from the boil kettle below. Pfafflin says that it takes about thirty minutes to fill the coolship, then about another half hour until it hits 167°F/75°C. “If we’re doing any hop additions in the coolship, we’ll add those at 176°F/80°C,” she says, adding that the Rauchbier, Czech-style Pilsner and Dark Lager, as well as Hopfenlager, get that treatment. “We almost exclusively use pellets because cleaning the whole cone hops out of a coolship is a pain in the ass,” she says.

Pfafflin sees the same trub separation, DMS blow off, and hop aroma benefits that many of the other brewers see with the coolship.

“There’s also a certain harmony to coolshipped lagers that can’t quite be put into words,” says Pfafflin. “It’s an element of je ne sais quoi, I suppose.”