Shop

How Precision Fermentation is Revolutionizing Craft Beer Technology

Making better beer -- with science!

This is a paid, sponsored post presented by Precision Fermentation.

Brewing is a delicate balancing act, marrying a precise scientific process with the room for creativity and art. To craft a fantastic beer, a brewer needs to follow some basic rules of nature.

From a scientific perspective, the key steps to making beer involve heating water with germinated grains for a certain amount of time to create an intense sugar solution – think of this like making oatmeal. Next, brewers boil the wort – as it’s now called – and hit it with a dose of hops for aroma, flavor, bittering, and pasteurization. As one of the final steps the liquid is cooled and makes its way to tanks for fermentation.

Here, the real magic begins. Brewers introduce yeast, which eats away at the sugars and produces the CO2 and alcohol we’ve come to know as beer. Since yeast is a very finicky living organism, producing the perfect environment for it to survive is integral to crafting the perfect beer and ideally requires constant time and attention. And yet, this magical method has mostly remained invisible to a brewer’s naked eye, taking place behind inches of stainless steel.

Until now.

With the mission to empower every brewery to leverage leading-edge fermentation science and technology to expand its artistic horizons and ensure exceptional product every time, Precision Fermentation created the BrewMonitor System to monitor fermentation in real-time.

Essentially peeling back the curtain on a non-transparent process, the BrewMonitor System allows brewers to consistently track what’s going on inside their tanks, creating a more consistent brewing process, helping brewers immediately solve potential problems before they manifest, and creating a new paradigm for fermentation management.

It’s an innovative technology that started as a simple idea and has since grown into a flourishing solution for craft breweries across the country.

The Idea for Real-Time Fermentation Monitoring

In 2015 Jared Resnick, Founder and CEO of Precision Fermentation, became a partner in Mimetics, a Durham-based technology company focused on finding the hidden patterns in complex time-series biological data. Mimetics’ research, science, and development sparked an idea for Resnick.

He wanted to create a startup company focused specifically on measuring real-time fermentation for the craft beer industry.

Combining forces with Michael Simon, who had close to 28 years of experience in financial services, data analytics, and sales, and Daniel Kulenic, whose years in the hospitality industry included owning and operating craft beer restaurants, among many others, Resnick started to bring his concept to life.

Simon loved the startup idea, but wanted to make sure that if he left the corporate world that it was for a business that “had legs,” says Simon.

As he started traveling around showing a deck for this new company to breweries in New York, North Carolina, and South Carolina he soon discovered that brewers were very interested in the prospect of observing and analyzing real-time fermentation. The response remained largely the same. “Wow, you track dissolved oxygen. That’s pretty significant,” says Simon, who notes that in addition to capturing dissolved oxygen (DO) the system also tabulates pH, gravity, pressure, internal and external temperatures, and conductivity. Each a crucial computation to a beer’s life cycle. The more he talked with brewers the more Simon uncovered that most breweries had no consistent, tangible way of analyzing fermentation in real-time. Or, if they did maintain a system of recording infrequent fermentation sampling on paper brew sheets, Excel spreadsheets or even through an ERP system, they very rarely went back and reviewed that information.

Essentially, an opportunity existed in the industry to use real-time fermentation tracking to improve a beer’s consistency and a brewery’s ability to reproduce a quality product at a high level, making the entire enterprise more profitable. And as Simon who is now the Chief Revenue Officer at Precision Fermentation, presciently points out, at the end of the day, “if you don’t have a buttoned up operational process it will be tough to keep the doors open.”

Similarly, Kulenic tapped into his own connections to vet the idea. He also found an overwhelming interest from brewers for a real-time fermentation tool.

“I reached out to friends in the industry and asked them what are your thoughts on this? Is it valid?”

Kulenic heard the positive feedback he needed.

With Simon and Kulenic, who is now the Chief People Officer at Precision Fermentation, on board, the startup went full steam ahead.

In August 2018 the company announced a Pilot Program, launching just in the southeastern United States to test the system and ensure they were moving in the right direction. The initial program provided immense guidance and direction to the product team allowing the company to expand its Pilot Program in April of 2019, again with the intent of “getting our product into brewer’s hands,” says Simon. With more critical feedback, Precision Fermentation added a few key refinements before officially releasing the BrewMonitor System nationwide last March.

And although the launch coincided with the COVID-19 pandemic, the company has started to make waves. Now, you can find BrewMonitor in breweries across five continents, on tanks that range in size from three to 300 barrels.

What is Precision Fermentation?

Overall, Precision Fermentation is on a mission to put eyes inside one of the most mysterious parts of the brewing processes. Monitoring fermentation at the exact moment it’s happening gives brewers the insights they need literally at their fingertips to ensure beer quality, prevent problems, and dramatically enhance control over the fermentation process.

At its most fundamental level the BrewMonitor System gives brewers an instant outlook on measuring variables crucial to the evolution of beer during fermentation including: pH, DO, temperature, pressure, gravity, and conductivity.

“We’re giving visibility to an opaque process,” says Simon.

Historically, monitoring a beer’s fermentation process varied from brewery to brewery, but could include taking readings only when a brewer knocks out (when a brewer stops the boil in the kettle and starts to cool the beer to transfer to the fermentation tanks) to sampling once a day once inside the tanks. Watching a fermentation was more of a wait and pray sort of process as opposed to an active engagement. This type of low frequency sampling can provide an inaccurate snapshot of the beer’s progress.

“Yeast is a dynamic, living breath organism,” says Simon. “As soon as you take a fermentation sample and bring it to the lab that sample might be invalid because the fermentation has moved. Which way did it move? Sideways? Up? Down? Not at all? A lot?”

The BrewMonitor System’s goal is to provide the constant benchmarking capability and fermentation tracking that gives the customer piece of mind and control with proactive means of intervention. Simon likens the system to, “providing a video or a movie that shows the progression of fermentation over time as opposed to a photograph or snapshot that people take once a day.”

Being able to track those crucial metrics and physically see the progression and rate of change of certain fermentation processes gives brewers tools to make adjustments or prevent problems on the fly.

Breweries like Bond Brothers Brewing Company in Cary, NC.

A Case Study: Bond Brothers Brewing Co.

Several years ago Whit Baker, the Brewmaster and Co-Founder at Bond Brothers, noticed that he was getting some poor fermentation off his flagship IPA resulting in an extra fruity beer. As mainly a taproom brewery focused heavily on its core brands and a rotating selection of limited-release beers, Bond Brothers makes it a priority to ensure consistency across its flagship beers. A huge variation in flavor for a core beer definitely presented a problem. Baker knew there was an issue, but he didn’t have a great way to “see” what was actually happening during fermentation.

Fortuitously, one of the members of Baker’s Cicerone study group happened to be Andy Morrison, National Account Executive for Precision Fermentation. He told Baker he might have a solution. “I said sign me up,” says Baker. “The box let us map the fermentation easily and effectively and use it to make changes.” Identifying the problem from the data collected from the BrewMonitor System, Bond Brothers actually neutralized and solved the problem.

Never before has the industry had the opportunity to demystify the previously cloudy cycle of fermentation. Instead of setting and forgetting it, Precision Fermentation offers a device that allows a brewer to set it, monitor it, adjust it, perfect it, solve it (if necessary), and produce the best beer possible at a consistent rate.

How Does The BrewMonitor System Work?

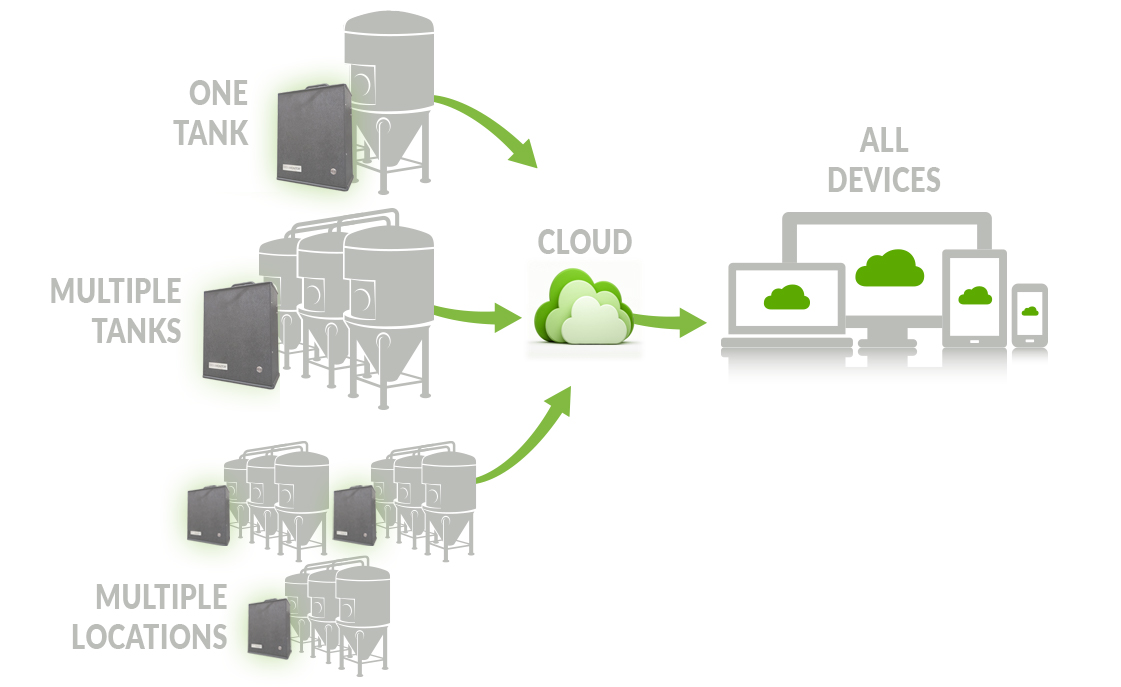

Essentially a shoebox-sized black box, the BrewMonitor Sensor Hub connects to a brewery’s existing fermentation tank at the sample port and circulates liquid across multiple sensors to instantly send data wirelessly to a brewer’s PC, tablet, or even phone.

The BrewMonitor Console continuously displays DO, pH, gravity, pressure, internal and external temperature, and conductivity of a beer in the tanks, offering complete fermentation process visibility and control that replaces trial-and-error measurements.

Beyond just remotely gathering the data and tracking the fermentation, the BrewMonitor Console presents this information in a useful way, tabulating graphs, letting brewers overlay graphs across multiple metrics, and even allowing brewers to set parameters across the spectrum of calculations. If a brew skews outside of the preset ranges the system will send an alert straight to a brewer’s phone or computer. Additionally, the Precision Fermentation team watches each and every live fermentation across all of its boxes, meaning their customer success team also has the power to step in and notify a brewer if anything with the current fermentation appears out of place.

“We’re like an ADT alarm system,” says Simon. “We have the expertise to say something if the brew doesn’t look right and call [brewers] so they can do something.”

This data-to-decision model ensures peak analysis and gives the brewers the opportunity to potentially alter the outcome to avoid having to blend, or worst case, dump a batch down the drain – and consequently dollars – because something went wrong that they couldn’t identify in time. It’s just one of the many advantages the BrewMonitor System gives a brewery to track their fermentation in real-time.

What Are the Benefits of Real-Time Fermentation?

At its core, the BrewMonitor System records crucial information that gives brewers the intelligence to streamline their craft beer quality management. Precision Fermentation has created a tool that builds from and expands off a somewhat outdated and infrequent fermentation sampling process

Whereas previously if a brewery sampled twice per day over the course of a 14-day fermentation while measuring five parameters they might collect 140 data points with the BrewMonitor System they’re gathering over 1,000 points of data a day or 14,000 data points over a 14-day fermentation.

For Baker, who says the brewery would previously sample maybe once or twice a day depending on how busy they were, Bond Brothers can now easily collect over 96 data points a day instead of just four data points from one small sample taken by hand.

“For me, the value is using [the BrewMonitor System] for the same beer over and over again over a long period of time to get a large data set for a single beer,” says Baker. “If you’re looking to take that kind of data every 10-15 minutes it’s impossible to pay someone to do that 24 hours a day.”

The system actually collects so much data that, in the beginning, Simon says when he asked brewers what they were going to do with all the data they’d often pause before answering because they’d just never had access to that much data before. They couldn’t contemplate what it all meant. But the more that brewers have used the real-time fermentation tracking software the more advantages appear.

While all the information has proven helpful, Baker says that the “two things that have been the most exciting to measure are gravity and pH because those two things allow Bond Brothers to determine if the beer is good, bad, or needs to be fixed.”

But, it varies for every brewer. “Ask five different breweries what they value most and you’ll get five different answers,” says Kulenic. “What’s exciting is that we can provide that wide range to our customers based on what their needs are.”

And, the exact needs of a potential customer are of the utmost importance to the Precision Fermentation team. “What we do is give a white-glove onboarding experience,” says Kulenic. Every morning the team goes through all the live, active fermentations. Yes, Precision Fermentation literally checks each of its current partners’ live fermentations to make sure everything is on track.

“Should anything warrant direct outreach we personally connect with clients to talk through and have a better understanding of what’s going on,” says Kulenic.

Beyond the technical benefits of the BrewMonitor System, perhaps one of the biggest advantages has been how the system impacts brewers’ lifestyles.

“I’ll never forget when one brewmaster asked me, ‘are you saying I can spend Christmas with my family?,’” remembers Kulenic. “We provided him with the opportunity to go home and know that everything is in line because he could monitor it all on his phone.”

Along with the scientific and lifestyle advantages, Kulenic says it’s crucial to understand that the BrewMonitor System isn’t replacing any of the artistry and hands-on work of brewing. In fact, it’s only enhancing it.

“We’re not trying to replace brewers. We’re trying to assist and help them improve on their craft,” says Kulenic. “We’re offering and supporting brewers to continue to be creative and be better.”

It all comes back to understanding what’s going on inside of the tanks

Simon continues, “I don’t care how artisanal you are, you still can’t see what’s going on through stainless steel unless you’re Superman. If you know what’s going on, then you can play with the dials….and create something really good that you can make again and again.”

What’s Next in Real-Time Fermentation?

Precision Fermentation has just started to explore the universe of real-time fermentation. After the COVID-19 pandemic hit in early 2020 the company pivoted and actually expanded, successfully deploying and testing systems in mead, kombucha, cider, and non-grain spirits. Additionally, the business is, “knocking on doors outside of North America,” says Simon, installing BrewMonitor Sensor Hubs across Europe as well as on other continents.

Last August, Precision Fermentation released the BrewMonitor System 2.0 as an upgrade to the current program, introducing new tools such as batch-to-batch quality analysis, yeast vitality trend analysis, centralized data management, and dynamic alerts, among others.

The industry is focused on craft and collaboration. And Precision Fermentations’ BrewMonitor System is giving brewers the precise controls they need to understand a living, breathing process, meaning they have the tools to make better brewing decisions.

And at the end of the day, that’s the ultimate goal: Better beer.

This is a paid, sponsored post presented by Precision Fermentation.

Liked this article? Sign up for our newsletter to get the best craft beer writing on the web delivered straight to your inbox.